29 years

together

Product description

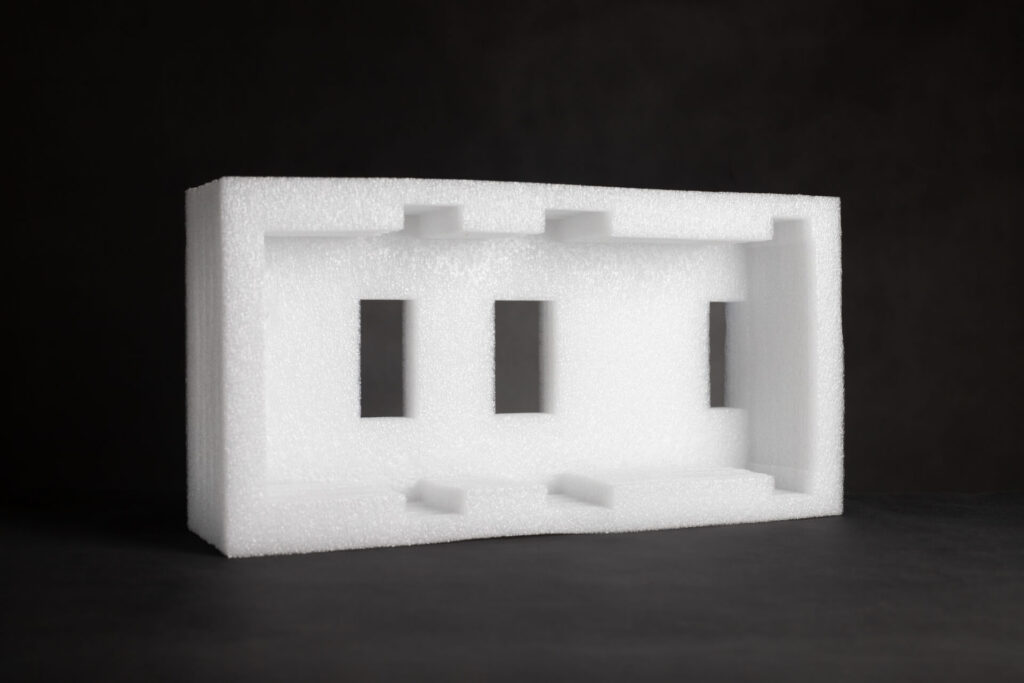

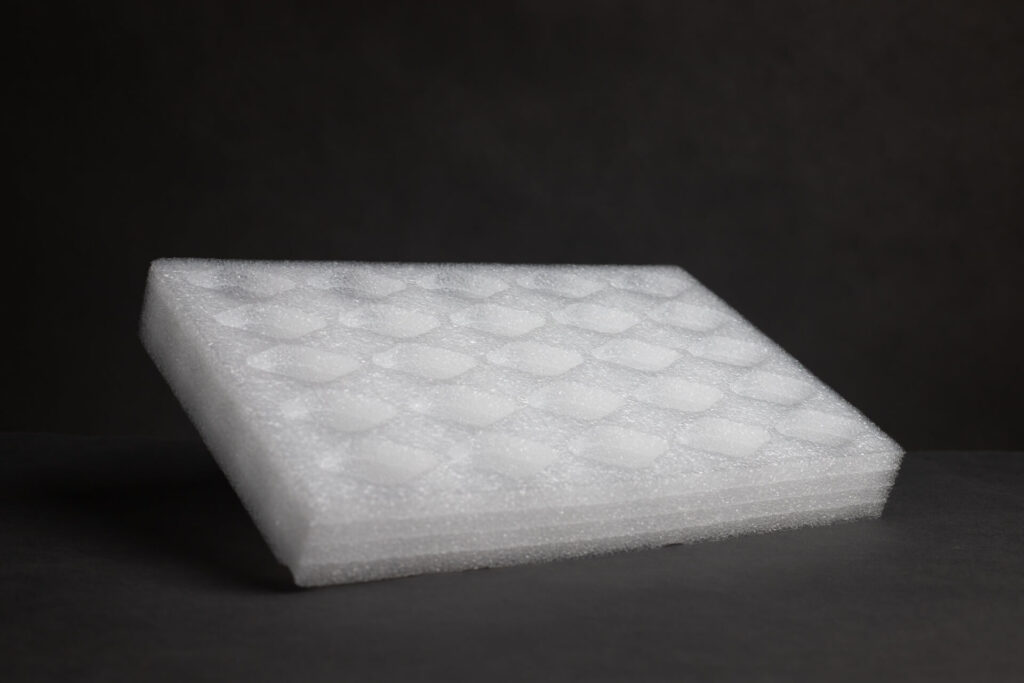

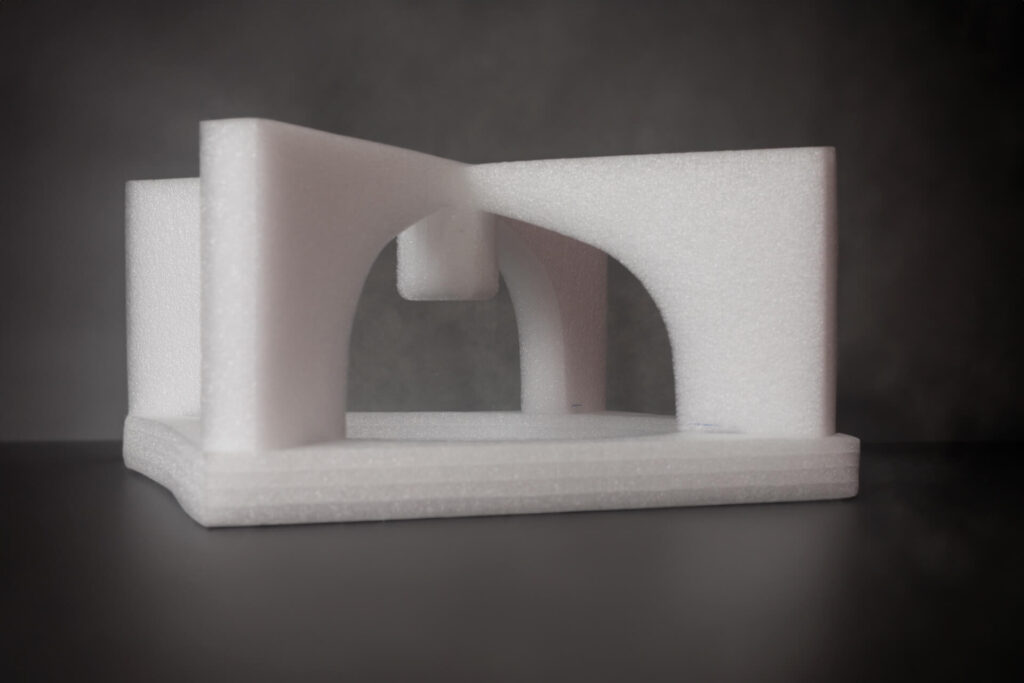

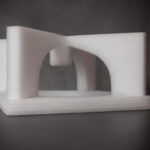

Gas-foamed polyethylene foam is a flexible, easy-to-process material with closed cells. It is an excellent packaging solution for many items requiring special protection. Polyethylene foam has a variety of applications.

Product features

- excellent protection of goods (high rebound resilience)

- lightweight (does not significantly increase the weight of protected products)

- easy to process (can be formed into various customized shapes)

- strong and unbreakable (as opposed to styrofoam)

- harmless

- eco-friendly (environment friendly)

- esthetic appearance (can be an additional element of product presentation)

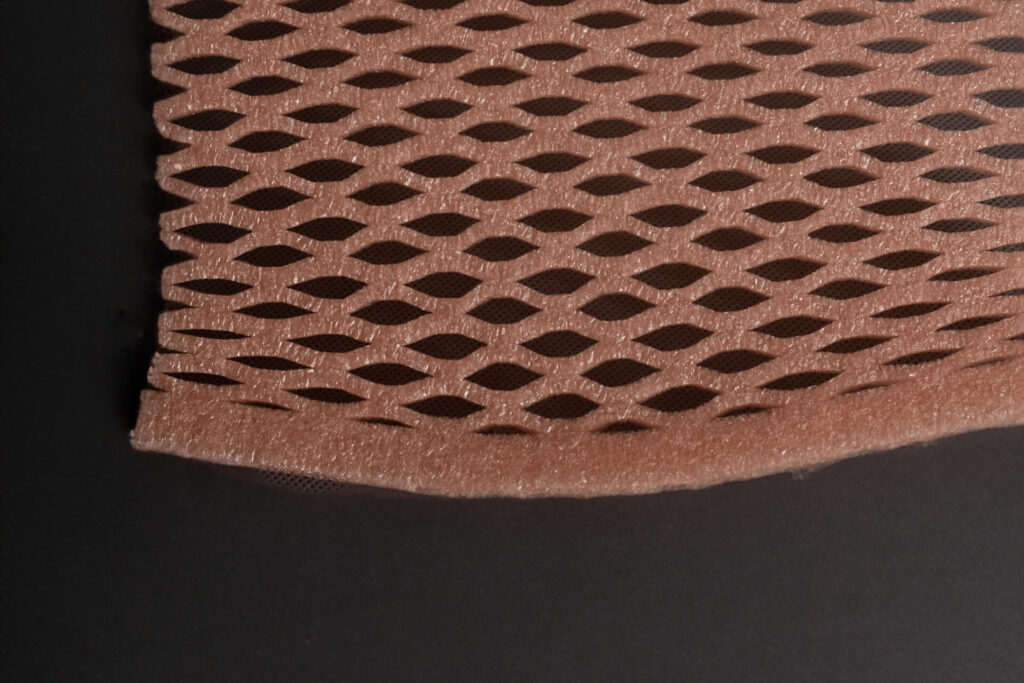

- can be bonded (without the use of glue) with other materials to form laminates (HDPE, PETM, adhesive film, bubble film, felt)

- chemically neutral (resistant to most chemicals)

- resistant to mold and moisture

- odorless

- 100% material recyclable

- can be produced with regranulate

- it is a good thermal insulation

- antistatic*

* (with the use of a special additive)

Product parameters

- density: 16 – 35 kg/m3

- thickness: 0,8 – 100 mm

- width: do 200 cm

- length: do 600 m

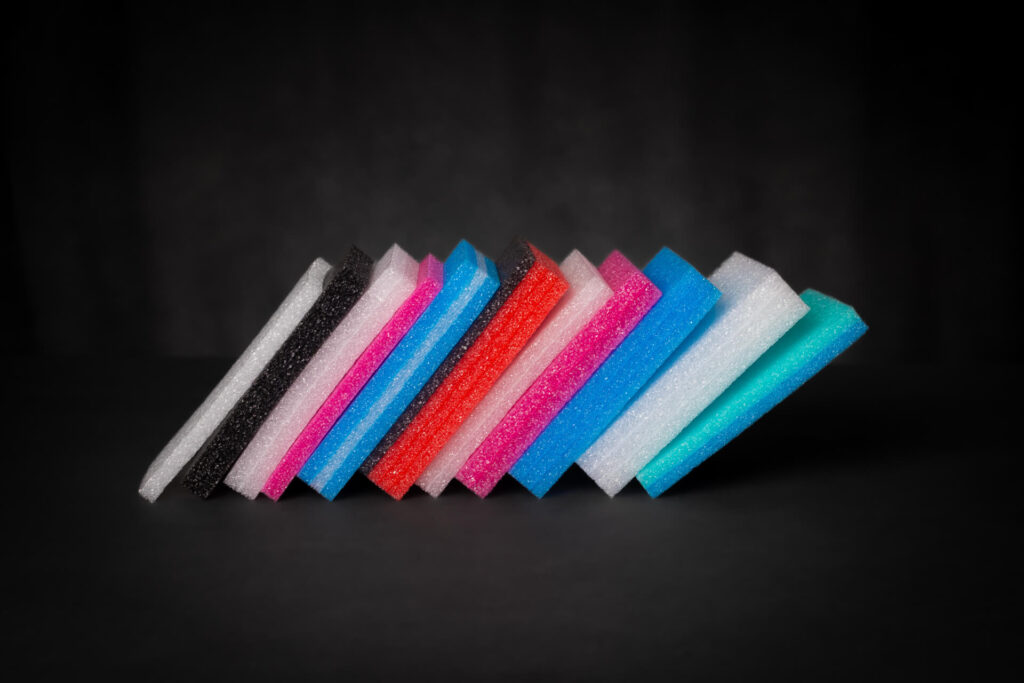

Color scheme

- basic: white, graphite

- special: blue, pink, celadon, yellow, etc. (RAL color can be selected)

Form

rolls, bags, sheets, boards, blanks, fittings, profiles

Use

- packaging industry: protection of electronics and household appliances, glass, ceramics, tools, metal parts, shadow boards, and many others

- construction: underlays for flooring panels, floating floors, jackets, pipe insulation, trampoline parks and playgrounds

- sports and tourism: camping mats, swimming pool and jacuzzi mats, mattresses, sports mats, for the production of backpacks and thermal bags

- rehabilitation equipment: stabilizers and spinal jackets.